Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

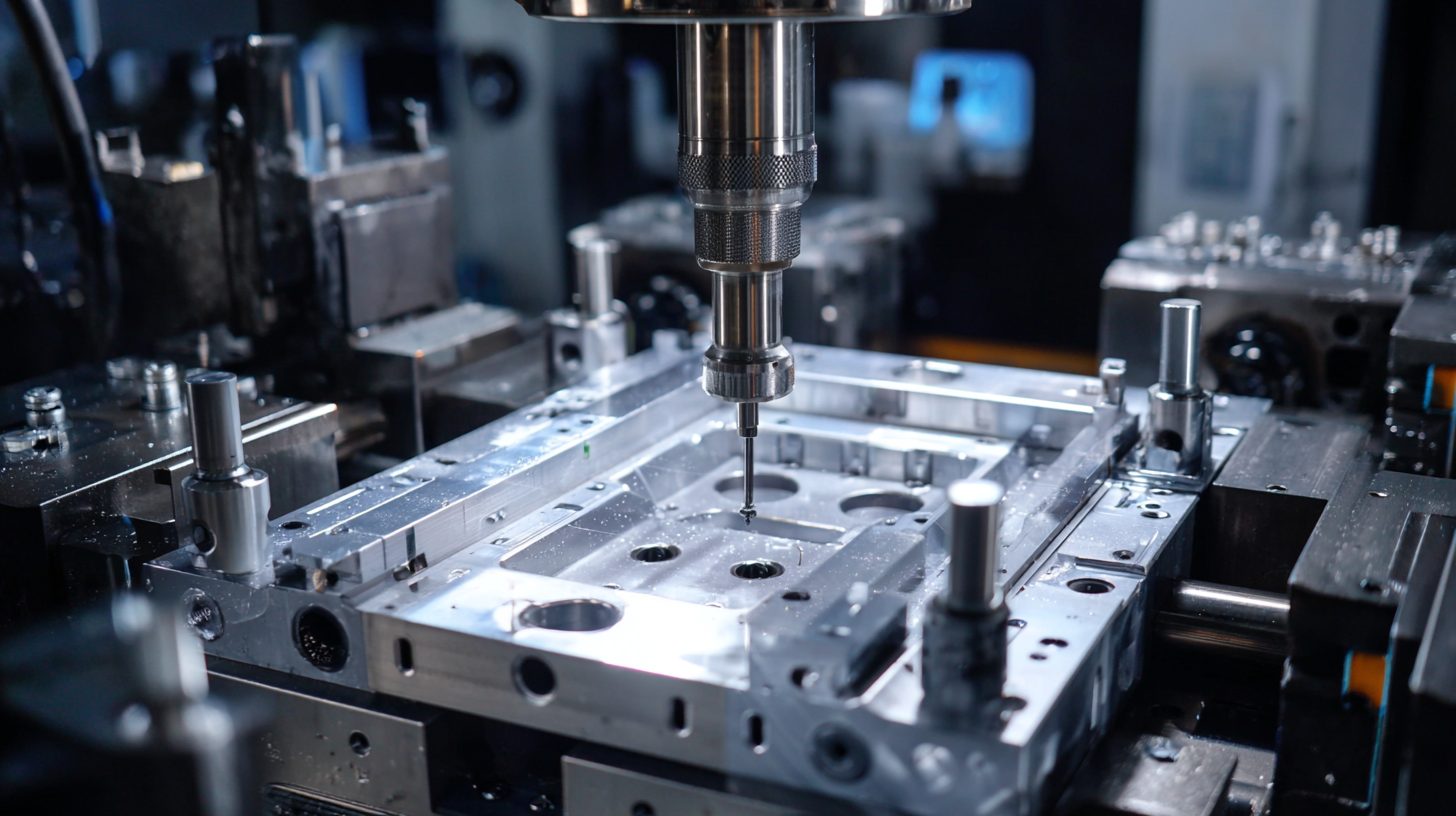

In the ever-evolving landscape of manufacturing, injection mold design has emerged as a pivotal factor in enhancing production efficiency and product quality. As industries strive to meet the demands of a fast-paced market, innovative techniques and digital technologies are reshaping the traditional approaches to mold creation. This exploration of advanced methodologies delves into how digitalization and data-driven solutions are revolutionizing injection mold design, thereby optimizing the production process. By integrating cutting-edge technologies such as computer-aided design (CAD), simulation software, and additive manufacturing, manufacturers can achieve unprecedented precision and flexibility.

This not only streamlines operations but also reduces lead times and costs, ultimately redefining the standards of manufacturing excellence. As we venture into this discussion, we highlight the transformative impact these advancements are making on the industry, paving the way for a new era of efficiency and efficacy in mold production.

Understanding the Basics of Injection Mold Design and Its Challenges

Injection mold design is a critical process in manufacturing that requires a deep understanding of various principles, materials, and methodologies. One of the main challenges faced during the design phase is achieving precision while minimizing production costs. Mold designers must consider factors such as the complexity of the part, the type of material being used, and the cooling process to ensure that the final product meets specifications without exceeding budget constraints.

Tips: When approaching injection mold design, always begin with a thorough understanding of the part geometry. Using software simulations can help visualize the flow of material and identify potential issues early in the design process. Additionally, collaborating with production teams during the design phase can provide valuable insights into manufacturability and cost-effectiveness.

Another significant challenge is managing the thermal dynamics within the mold. Inadequate cooling can lead to longer cycle times and affect part quality. Designers must optimize cooling channels to ensure even heat distribution and reduce cycle times. This meticulous attention to thermal management can greatly enhance production efficiency.

Tips: Regularly review and refine cooling strategies based on feedback from trial runs. Incorporating temperature sensors can provide real-time data, helping to adjust processes on the fly. Properly designed cooling systems not only improve efficiency but also prolong the lifespan of the molds.

Innovative Materials and Technologies Transforming Mold Production Processes

The landscape of injection mold design is undergoing significant transformation, largely influenced by innovative materials and advanced technologies. As industries strive for enhanced production efficiency, the integration of new materials plays a pivotal role. Recent reports indicate a robust growth in the plastic processing auxiliary equipment market, projected to reach substantial figures by 2030. This growth underscores the critical need for manufacturers to adopt cutting-edge technologies that not only reduce costs but also streamline the production processes.

Digital innovations in the injection molding sector are becoming increasingly essential. For instance, new Design for Manufacturing (DFM) tools offer unprecedented visibility throughout the molding process, significantly mitigating potential production delays. Such technological advancements pave the way for high-performance molds made from modern materials, which can enhance durability and sustainability. As the industry shifts towards more adaptable and innovative solutions, the potential for optimizing production lines and achieving eco-friendly manufacturing becomes more promising.

Embracing these novel approaches could redefine the efficiency benchmarks within the injection mold production arena.

Integrating AI and Automation for Enhanced Mold Design Efficiency

The integration of AI and automation into injection mold design has sparked a significant transformation in production efficiency. By leveraging advanced algorithms and machine learning, designers can now analyze vast amounts of data to predict the optimal design parameters. These technologies streamline the design process, reduce human error, and minimize the time required to go from concept to production. As a result, manufacturers can produce high-quality molds with enhanced precision and improved turnaround times.

Moreover, automation plays a crucial role in implementing these designs. Automated systems can perform repetitive tasks with consistent accuracy, allowing engineers to focus on more complex problem-solving aspects. This synergy between AI and automation not only accelerates the design cycle but also fosters innovation by enabling rapid prototyping and testing of novel concepts. The outcome is a more agile manufacturing environment where efficiency and creativity coexist, ultimately leading to better products and increased market competitiveness.

The Role of Simulation Software in Optimizing Mold Performance

In the realm of injection mold design, simulation software has become an indispensable tool for optimizing mold performance and enhancing production efficiency. According to a report by MarketsandMarkets, the simulation software market in manufacturing is projected to reach $16.1 billion by 2026, growing at a CAGR of 14.7%. This growth is indicative of the industry's shift towards leveraging advanced technologies to minimize production costs and reduce lead times. By utilizing these sophisticated software solutions, manufacturers can simulate various molding processes, allowing them to predict potential issues and make data-driven adjustments before the actual production begins.

Furthermore, a study by the American Society of Mechanical Engineers (ASME) highlights that companies employing simulation software experience a reduction in material waste by up to 20%, alongside a significant increase in mold lifecycle by approximately 30%. These savings not only translate to cost-effectiveness but also contribute to a more sustainable manufacturing process. As the demand for high-quality components intensifies, the integration of simulation tools into injection mold design becomes critical, ensuring that manufacturers can meet and exceed client expectations while maintaining efficiency and productivity.

Sustainable Practices in Injection Mold Design: Reducing Waste and Energy Use

Sustainable practices in injection mold design are increasingly vital as industries seek to minimize their environmental impact. By focusing on reducing waste and energy use, manufacturers can not only enhance their green credentials but also optimize production efficiency. Implementing design for manufacturability (DFM) principles can significantly contribute to sustainability, allowing for molds that require fewer resources and generate less scrap during the production process.

Tips: Consider using simulation software to analyze mold designs early in the process. This can help identify potential inefficiencies and enable adjustments that minimize material waste before production begins. Additionally, exploring biodegradable or recyclable materials for mold construction can further enhance sustainability, ensuring that the entire lifecycle of the mold is considered.

Moreover, integrating energy-efficient heating and cooling systems in the molding process can dramatically reduce energy consumption. By adopting these technologies, manufacturers can not only lower their operational costs but also reduce their carbon footprint. It's essential to consistently seek out innovations that align sustainability with production goals to create a more efficient and responsible manufacturing environment.