Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

The injection moulding process is a pivotal manufacturing technique that transforms raw materials into intricate, durable components used across various industries. As a beginner stepping into the world of manufacturing, understanding this complex process can be daunting yet incredibly rewarding. This guide aims to demystify the injection moulding process by breaking it down into easily digestible segments, exploring its fundamental principles, operational steps, and the equipment involved.

Whether you are a student, a hobbyist, or someone considering a career in manufacturing, this comprehensive overview will provide you with the essential knowledge you need to grasp the nuances of injection moulding. By the end of this guide, you'll have a clearer picture of how this versatile process works and its significance in producing high-quality products efficiently.

Understanding the Basics of Injection Moulding: Key Concepts Explained

Injection moulding is a critical manufacturing process widely used in the plastic industry, allowing for the efficient production of complex shapes and parts. At its core, this process involves melting plastic pellets and injecting the molten material into a mold under high pressure. According to a report by Grand View Research, the global injection moulding market is expected to reach $450 billion by 2027, showcasing its importance in various sectors such as automotive, consumer goods, and healthcare.

One of the key concepts in injection moulding is the material selection. Different plastics offer varying properties like strength, flexibility, and heat resistance, making it essential to choose the right polymer for your application. For instance, polypropylene is favored for its excellent chemical resistance and durability, while polycarbonate is often used for its high impact resistance and optical clarity. Understanding these material properties can significantly influence the final product's performance and cost.

**Tip:** When starting with injection moulding, always ensure that the material compatibility with your mold design is checked to avoid costly errors during production. Additionally, keep an eye on cycle times and machine settings to optimize efficiency and maintain quality control. Balancing these factors can lead to a smoother production process and ensure that the finished product meets precise specifications.

| Key Concept | Description | Importance |

|---|---|---|

| Injection Moulding | A manufacturing process for producing parts by injecting molten material into a mould. | Efficient for mass production of complex shapes. |

| Thermoplastics | Plastics that can be melted and reshaped multiple times. | Versatile and widely used in injection moulding. |

| Mould Design | The process of creating the die used for shaping the injected plastic. | Critical for achieving the desired part specifications. |

| Cycle Time | The total time taken to produce one part. | Directly affects production efficiency and cost. |

| Clamping Force | The force applied to keep the mould closed during injection. | Ensures that the mould does not open prematurely, avoiding defects. |

| Quality Control | Systems and processes put in place to ensure consistent quality of moulded parts. | Essential for meeting specifications and customer requirements. |

The Step-by-Step Injection Moulding Process: From Design to Production

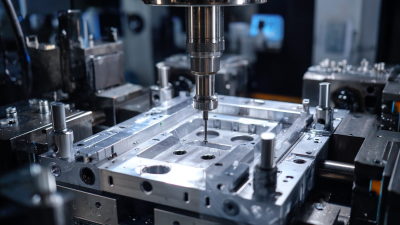

The injection moulding process is a highly efficient method used to produce a wide range of plastic parts, and understanding its step-by-step journey from design to production is essential for beginners. The process begins with the creation of a detailed design, where engineers utilize computer-aided design (CAD) software to visualize the product. This initial phase is crucial, as it lays the groundwork for the subsequent steps, ensuring that all dimensions and specifications are precisely defined.

Once the design is finalized, the next step involves creating a mould. This mould is typically made from metal and is crafted with extreme precision to match the CAD design. Afterward, the material, usually in the form of plastic pellets, is heated until it becomes molten. The molten plastic is then injected into the mould under high pressure, allowing it to fill every cavity. After the material cools and solidifies, the mould is opened, and the finished part is ejected. This entire process can be repeated rapidly, making injection moulding a cost-effective method for mass production, particularly for complex shapes and high-volume outputs. By grasping these fundamental steps, beginners can better appreciate the intricacies of injection moulding and its applications across various industries.

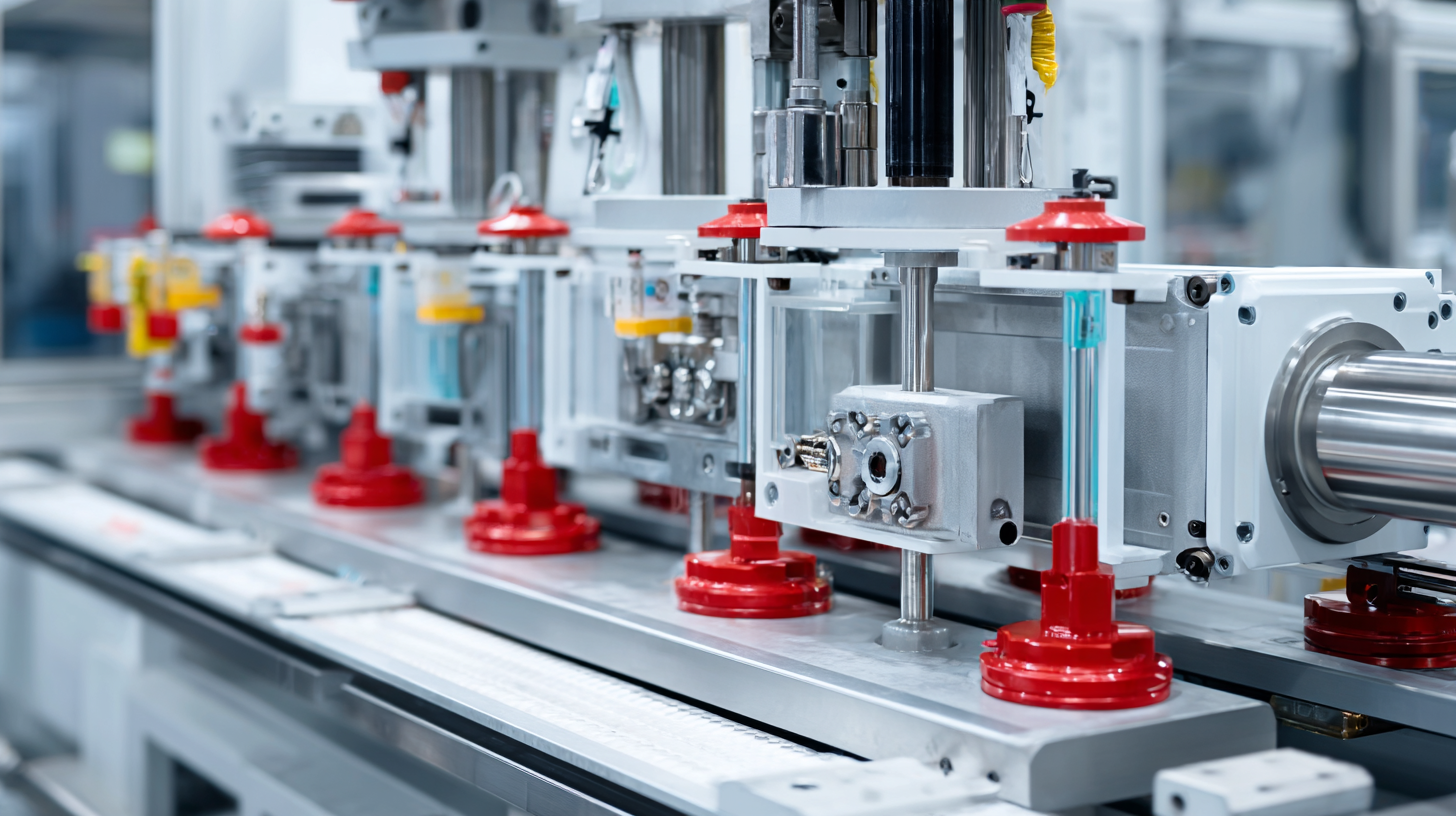

Essential Equipment and Materials Used in Injection Moulding

The injection molding process is heavily reliant on a variety of essential equipment and materials, which are critical to its efficiency and quality. A significant component is the injection molding machine, which is expected to see substantial growth in the coming years. For instance, the injection molding machines market in India alone is projected to reach approximately USD 830.9 million by 2025, with an impressive CAGR of 8.0% anticipated through to 2035. As the demand for plastic components increases across various industries, such as aerospace and medical, manufacturers are investing in advanced machinery to meet these needs.

In addition to machines, the choice of materials plays a pivotal role in the injection molding process. Innovations within the Metal Injection Molding (MIM) sector, particularly in Asia, highlight a shift in feedstock sourcing and material usage to enhance product quality. Additionally, there’s a notable demand for auxiliary equipment in plastic processing, projected to grow at a CAGR of 4.1% from 2024 onwards, reaching a market size of approximately USD 7405.6 million by 2030. These developments underscore the increasing complexity and specialization within the injection molding field, making the right choice of equipment and materials indispensable for manufacturers aiming to excel in a competitive landscape.

Common Applications and Industries Benefiting from Injection Moulding

Injection moulding is a widely utilized manufacturing process that offers significant advantages across various industries. Its efficiency and versatility make it integral in sectors such as automotive, consumer goods, electronics, and medical devices. The process allows for high-volume production of complex parts with precision and minimal waste, making it a go-to method for many manufacturers looking to produce plastic and composite materials.

Tip: When considering injection moulding for a specific application, it's crucial to understand the material properties required for your product. For instance, using Polymer Matrix Composites (PMCs) can enhance strength while reducing weight, which is particularly beneficial in the automotive industry.

Additionally, industries are increasingly benefiting from advancements in injection moulding technologies such as Liquid Silicone Rubber (LSR) injection moulding. This process not only produces high-quality parts but also addresses evolving market demands for flexibility and durability.

Tip: Investing in the right type of injection moulding machine, whether hydraulic, electric, or hybrid, can greatly impact production efficiency and part quality. Evaluating the specific needs of your production run will ensure optimal performance and cost-effectiveness.

Troubleshooting Common Issues in the Injection Moulding Process

Injection moulding is a complex process that can present various challenges, especially for beginners. One common issue is variations in dimensional accuracy, which can occur due to improper cooling or inconsistent material flow. To troubleshoot this, it's essential to ensure that the mould temperature is adequately controlled and that the injection speed is optimized. Regularly monitoring the material flow and adjusting the machine settings can significantly improve the precision of the final product.

Injection moulding is a complex process that can present various challenges, especially for beginners. One common issue is variations in dimensional accuracy, which can occur due to improper cooling or inconsistent material flow. To troubleshoot this, it's essential to ensure that the mould temperature is adequately controlled and that the injection speed is optimized. Regularly monitoring the material flow and adjusting the machine settings can significantly improve the precision of the final product.

Another frequent problem is surface defects, such as sink marks or short shots. These are often caused by insufficient material being injected into the mould or poor venting, which prevents air from escaping. To address these issues, operators should consider increasing the injection volume or enhancing the venting design of the mould. Implementing a proper cooling cycle is also crucial, as it affects the surface finish and overall integrity of the parts produced. By understanding these common pitfalls and their solutions, beginners can navigate the injection moulding process with greater confidence and efficiency.

Related Posts

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products

-

Exploring Innovations in Plastic Manufacturing: Sustainable Solutions for Tomorrow

-

Innovative Molding Tools for Streamlined Manufacturing Processes

-

Exploring the Future of Union Tool: Innovations and Applications in Today’s Industry

-

Transforming Manufacturing Efficiency with Advanced Plastic Injection Machine Technology

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency