How Injection Mold Manufacturing is Revolutionizing Product Development in 2023

In 2023, the landscape of product development is undergoing a profound transformation, largely driven by advancements in injection mold manufacturing. This manufacturing technique, known for its ability to produce high-precision and complex parts at scale, has seen a significant increase in adoption across various industries. According to a report by MarketsandMarkets, the global injection molding market is expected to reach $300 billion by 2026, which indicates an annual growth rate of over 5%. As companies strive for faster time-to-market and improved product quality, effective utilization of injection molding technology is becoming more essential than ever.

Industry expert Dr. Thomas Hamburg, a leading figure in injection mold manufacturing, emphasizes this shift: “The evolution of injection mold technology not only enhances efficiency but also opens avenues for innovative product designs that were previously unfeasible.” The integration of state-of-the-art materials and smart manufacturing practices has enabled businesses to push the boundaries of product development, allowing for intricate designs that cater to consumer demands with unmatched accuracy. As we delve deeper into the implications of injection mold manufacturing, it becomes clear that this innovative approach is not merely a trend but a pivotal element of modern manufacturing strategy for businesses aiming to stay competitive in a rapidly changing marketplace.

The Role of Advanced Injection Mold Technologies in Rapid Prototyping

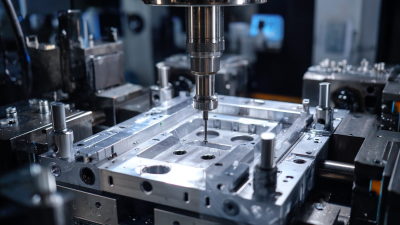

Advanced injection mold technologies are at the forefront of revolutionizing rapid prototyping in 2023. These innovative techniques allow manufacturers to create highly detailed and precise prototypes in significantly shorter timeframes. By utilizing advanced materials and streamlined manufacturing processes, companies can now test and iterate their designs more efficiently. This speed not only reduces time-to-market but also allows for more flexibility in design alterations, catering to the fast-paced demand of modern consumer expectations.

Moreover, the integration of automation and computer-aided design (CAD) with injection molding enhances the accuracy and repeatability of prototypes. This synergy enables engineers and designers to visualize their concepts in real-time, making adjustments that were previously cumbersome or costly. As a result, businesses are embracing advanced injection mold technologies to foster creativity and innovation in product development, leading to a more competitive edge in the marketplace. The ability to quickly produce functional prototypes facilitates better collaboration between teams and accelerates product testing, ultimately shaping the future of manufacturing.

Key Industry Statistics Highlighting Cost Reductions in Injection Mold Manufacturing

In 2023, injection mold manufacturing has emerged as a pivotal force in product development, underpinned by significant cost reductions that have captured industry attention. According to a report by Grand View Research, the global injection molding market size is projected to reach USD 304.79 billion by 2028, expanding at a compound annual growth rate (CAGR) of 3.8%. This growth is largely attributed to innovations in manufacturing techniques that enhance efficiency and reduce production costs, making it increasingly feasible for companies to bring products to market swiftly.

Moreover, studies indicate that utilizing advanced injection molding technology can reduce manufacturing costs by up to 30%. This is particularly impactful for small to medium-sized enterprises (SMEs) that may lack the resources to absorb high manufacturing expenses. A survey by Accenture found that 78% of manufacturing leaders believe that optimized injection molding processes have directly led to faster turnaround times and lower unit costs. As firms continue to leverage these advancements, injection mold manufacturing is not only revolutionizing how products are developed but also making it possible for businesses to remain competitive in a rapidly evolving marketplace.

Integrating Digital Twins in Injection Mold Design for Enhanced Product Accuracy

The integration of digital twins into injection mold manufacturing is profoundly enhancing product accuracy and efficiency in 2023. Digital twins—virtual replicas of physical assets—allow manufacturers to simulate the injection molding process, leading to an impressive 40% reduction in prototyping time, as reported by the latest research from Deloitte. By leveraging real-time data and advanced analytics, engineers can identify potential flaws in the mold design early in the development process, minimizing costly revisions and delays.

To maximize the benefits of digital twins, manufacturers should consider implementing a continuous feedback loop between the physical molds and their virtual counterparts. This not only improves design accuracy but also allows for predictive maintenance, reducing downtime by up to 25%, according to McKinsey & Company. The synergy between digital twins and injection mold design streamlines the development cycle, resulting in faster time-to-market for innovative products.

**Tip:** When integrating digital twins, invest in robust data management systems to ensure seamless communication between the physical and virtual models. Additionally, training personnel on digital twin technology is essential to fully leverage its potential in injection mold design. Regularly updating the digital twin with real-time data will further enhance accuracy and efficiency.

Impact of Digital Twins on Product Development in 2023

Sustainable Practices in Injection Mold Manufacturing Driving Eco-Friendly Innovations

In 2023, sustainable practices in injection mold manufacturing are driving significant eco-friendly innovations that reshape product development. Companies are increasingly prioritizing environmentally friendly processes, such as low-pressure injection molding, which offers a sustainable alternative to traditional methods. This innovative approach reduces energy consumption and waste, supporting the industry's transition toward more responsible production techniques.

Furthermore, the global shift towards biodegradable packaging solutions is creating a robust market for molded pulp packaging. With the consumer demand for eco-conscious products on the rise, manufacturers are leveraging advances in material science to develop lighter, more sustainable options. These innovations not only enhance product performance but also minimize environmental impact, illustrating the industry's commitment to creating a greener future. As sustainable practices continue to evolve, they promise to redefine how products are developed and delivered, promoting a more sustainable economy.

Emerging Trends in Injection Mold Materials for Enhanced Durability and Performance

In 2023, injection mold manufacturing continues to evolve drastically, driven by advancements in materials that enhance durability and performance. Emerging trends reflect a significant shift towards the utilization of advanced thermoplastics and composites, which are rapidly becoming essential in various sectors, including railcar components. These innovations not only improve the longevity of products but also contribute to more sustainable production practices, aligning with global efforts toward eco-friendly solutions.

Tips: When considering materials for injection molding, it's vital to assess the specific performance requirements and environmental implications. Look for options that provide better UV aging resistance and compatibility, such as 3D-printed biomass materials-composites. Additionally, keeping abreast of market forecasts—like the anticipated growth of the transparent polyamides market—can guide manufacturers in making informed choices that align with industry trends.

Furthermore, the rise of nano coating technology is set to bolster product capabilities substantially. By integrating these coatings with injection molded components, manufacturers can achieve enhanced resistance to wear and tear, thus extending the lifecycle of their products. Embracing these emerging trends will not only improve product performance but also meet the growing demand for innovative and sustainable manufacturing solutions.

How Injection Mold Manufacturing is Revolutionizing Product Development in 2023 - Emerging Trends in Injection Mold Materials for Enhanced Durability and Performance

| Material Type | Durability Rating | Applications | Cost per Unit ($) | Sustainability Rating (1-10) |

|---|---|---|---|---|

| Polycarbonate | 9/10 | Consumer Electronics, Automotive | 2.50 | 7 |

| Nylon | 8/10 | Textiles, Automotive | 1.70 | 6 |

| ABS Plastic | 7/10 | Household Goods, Toys | 1.00 | 5 |

| Polyethylene | 6/10 | Packaging, Bottles | 0.80 | 8 |

| PBT (Polybutylene Terephthalate) | 8/10 | Electrical Components, Automotive | 3.00 | 7 |

Related Posts

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products

-

Exploring the Future of Union Tool: Innovations and Applications in Today’s Industry

-

Transforming Manufacturing Efficiency with Advanced Plastic Injection Machine Technology

-

Innovative Molding Tools for Streamlined Manufacturing Processes

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners