Exploring the Future of Union Tool: Innovations and Applications in Today’s Industry

The future of the union tool industry is poised for transformative growth, driven by advancements in technology and evolving market demands. According to a recent report by Market Research Future, the global market for union tools is projected to reach $XX billion by 2025, reflecting a CAGR of XX%. Innovations in digital technologies, including AI and IoT, are set to redefine traditional manufacturing processes, enhancing efficiency and precision in tool application. Furthermore, surveys conducted by the American National Standards Institute reveal that over 70% of manufacturers are investing in smart tools to improve productivity and reduce operational costs. This exploration will delve into the latest trends, innovations, and practical applications of union tools in today’s industrial landscape, underscoring their vital role in sustaining competitive advantage and fostering industry growth.

Navigating Technological Advancements in Union Tool Manufacturing

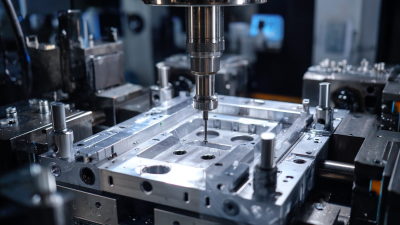

The manufacturing landscape of union tools is undergoing a significant transformation, driven by rapid technological advancements. According to a report by MarketsandMarkets, the global tool manufacturing market is expected to reach $210 billion by 2026, growing at a CAGR of 4.5%. This growth is largely attributed to the integration of smart technologies, such as IoT and AI, which are reshaping production processes and enhancing operational efficiency. Union tool manufacturers are leveraging these advancements to optimize design, reduce lead times, and improve quality control, establishing a competitive edge in the industry.

Moreover, the adoption of additive manufacturing is revolutionizing union tool production. A study from Wohlers Associates indicates that the additive manufacturing market is projected to grow to $35.6 billion by 2024. This shift allows for more intricate designs and materials that were previously unattainable with traditional methods. As manufacturers explore these innovations, the ability to create customized tools tailored to specific applications is becoming increasingly feasible, setting a new standard for performance and efficiency. The future of union tools clearly lies in navigating these technological advancements, paving the way for enhanced productivity across various sectors.

Identifying Key Innovations Transforming Union Tool Applications

The Union Tool industry is experiencing significant transformations driven by key innovations that are reshaping applications across various sectors. According to a report by Market Research Future, the global tooling market is expected to reach $130 billion by 2027, with a CAGR of over 5%. This growth is largely attributed to advances in materials science and automation technologies, which enhance productivity and efficiency in manufacturing processes.

One of the most notable innovations is the integration of smart technology into tooling systems. Smart tooling systems equipped with IoT (Internet of Things) capabilities allow for real-time data analysis and predictive maintenance. A study by ResearchAndMarkets indicates that the adoption of smart manufacturing technologies can improve operational efficiency by up to 25%. This level of insight enables companies to reduce downtime and improve product quality, making it a key focus for the future of Union Tool applications.

Tip: When considering new tooling solutions, invest in those that offer smart capabilities. This will not only streamline your processes but also provide valuable data insights that can enhance decision-making. Additionally, look for tools made from advanced materials that reduce wear and extend lifespan, ultimately leading to cost savings in the long run.

Integrating Smart Technologies in Union Tool Design and Usage

The integration of smart technologies into union tool design and usage is revolutionizing the manufacturing industry, enhancing productivity and precision. According to a recent report by MarketsandMarkets, the global smart manufacturing market is projected to grow from $214 billion in 2021 to $384 billion by 2026, with a compound annual growth rate (CAGR) of 12.4%. This growth underscores the increasing reliance on intelligent systems, such as IoT-connected tools, that provide real-time data analytics and machine learning capabilities to improve operational efficiency.

Incorporating smart technologies into union tools not only boosts performance but also reduces operational costs. For example, tools equipped with sensors can monitor their condition and predict maintenance needs, minimizing downtime and extending tool lifespan. Additionally, advanced designs that integrate AI algorithms enable manufacturers to develop custom solutions tailored to specific applications, leading to enhanced precision and reduced waste.

Tips: When considering the integration of smart technologies into union tool usage, focus on collecting data that reveals real-time performance insights. Also, evaluate existing processes to identify potential areas for improvement through automation. Finally, ensure that staff are trained to utilize these smart tools effectively for maximum impact.

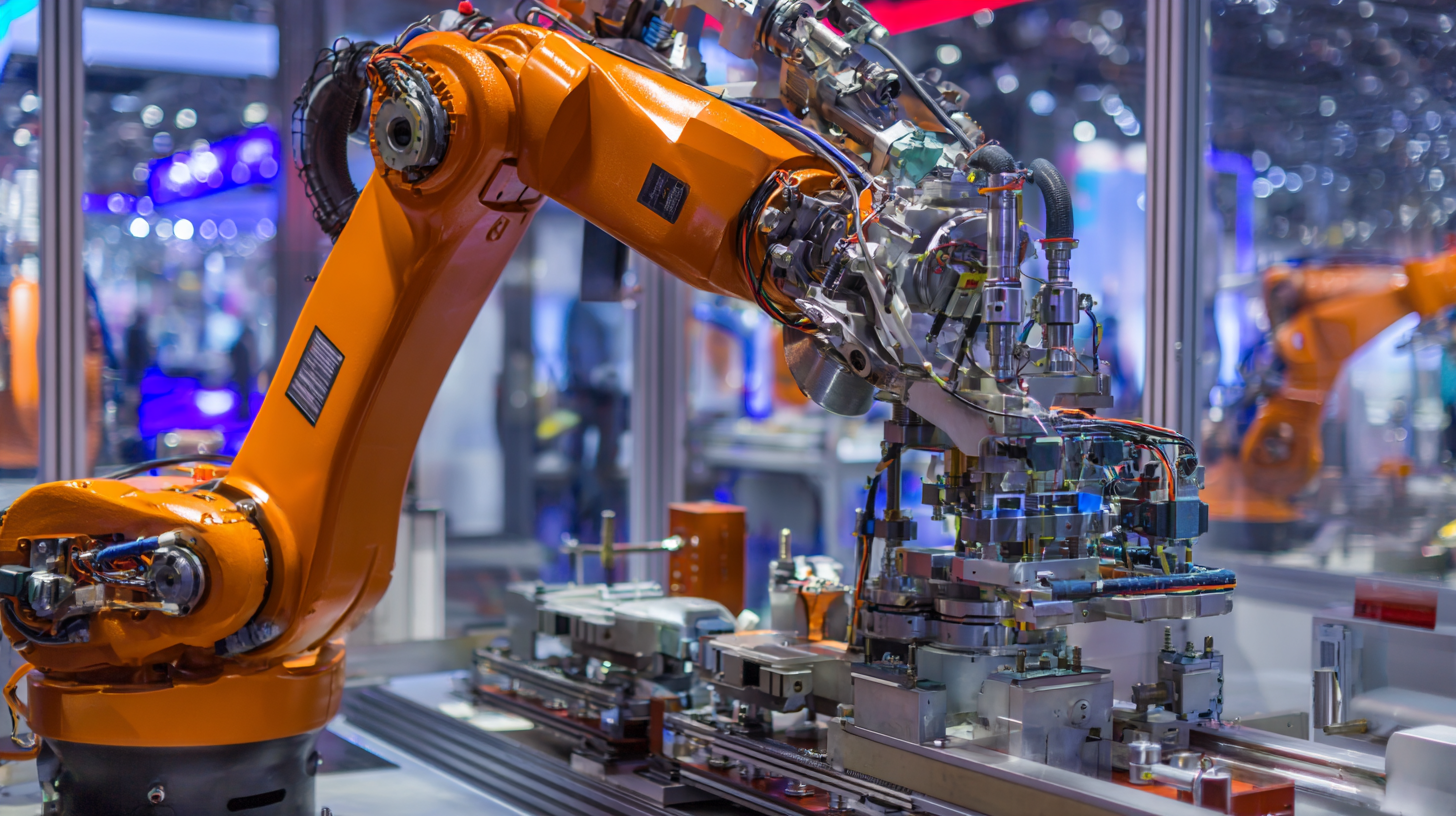

Enhancing Productivity through Automation in Union Tool Industries

In today's rapidly evolving industrial landscape, automation is redefining productivity standards within the union tool industry. By integrating advanced technologies such as robotics and AI, companies are not only streamlining production processes but also enhancing accuracy and speed. This transformation enables manufacturers to respond more swiftly to market demands, ultimately increasing their competitive edge. Automation facilitates not just efficiency, but also the ability to innovate, allowing businesses to explore new designs and functionalities that were previously unfeasible.

**Tip:** Consider investing in training programs for your workforce to ensure they are well-equipped to adapt to new automation technologies. This can significantly reduce resistance to change and enhance the overall productivity of the workforce.

Moreover, application of data analytics tools within automated systems helps in predictive maintenance, minimizing downtime, and optimizing the supply chain. With real-time data insights, firms can make informed decisions that bolster operational efficiency and resource management. Emphasizing a culture of innovation through automation can lead to breakthroughs that set a company apart in a crowded market.

**Tip:** Regularly review and evaluate the performance of your automated systems to identify areas for improvement. Small adjustments can lead to substantial gains in productivity and cost savings over time.

Exploring the Future of Union Tool: Innovations and Applications in Today’s Industry

| Innovative Technology | Application Area | Projected Impact | Adoption Rate (%) |

|---|---|---|---|

| AI-Powered Analytics | Manufacturing Optimization | 30% increase in efficiency | 65% |

| Robotic Automation | Assembly Lines | 50% reduction in labor costs | 75% |

| IoT Integration | Maintenance Management | 25% reduced downtime | 70% |

| Advanced Materials | Tool Manufacturing | 15% longer tool lifespan | 60% |

| 3D Printing | Prototyping | 40% faster production times | 50% |

Evaluating Future Trends and Market Demands for Union Tools

The market for union tools is poised for significant evolution as industries increasingly prioritize efficiency and adaptability. According to a report from Global Industry Analysts, the global market for industrial tools is expected to reach $100 billion by 2026, driven by advancements in automation and precision engineering. With the rise of smart manufacturing, the demand for innovative union tools that enhance productivity and precision continues to grow. Companies are investing in tools that leverage IoT technology, ensuring real-time data collection and analytics to optimize operations.

As industries adapt to changing market demands, the focus will also shift towards sustainable practices. A recent study by ResearchAndMarkets projected that the green tool market will witness a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. This trend highlights the increasing necessity for union tools that not only meet performance expectations but also align with environmental standards. By integrating sustainable materials and energy-efficient processes, manufacturers can respond effectively to consumer preferences for eco-friendly products, positioning themselves favorably in an increasingly competitive marketplace.