Exploring Innovations in Plastic Manufacturing: Sustainable Solutions for Tomorrow

The plastic manufacturing industry is at a pivotal crossroads, with the global market anticipated to reach $1 trillion by 2026, according to a report by Grand View Research. As environmental concerns mount and regulatory frameworks tighten, companies are increasingly seeking sustainable innovations to redefine traditional practices. The shift towards eco-friendly materials and processes is not just a trend; it is a necessity. For instance, the World Economic Forum reports that only 9% of plastic produced globally is recycled, highlighting a significant gap in sustainability efforts. Embracing digital technologies alongside advanced manufacturing solutions is essential for optimizing resource efficiency and reducing waste. This article delves into groundbreaking innovations in plastic manufacturing, focusing on sustainable practices that promise to shape the future of the industry and drive a circular economy.

Innovative Materials: The Future of Eco-Friendly Plastics in Manufacturing

Innovative materials are at the forefront of the movement towards eco-friendly plastics in manufacturing. As industries strive to reduce their carbon footprint, new alternatives are being developed to replace traditional plastics with biodegradable or recycled variants. Innovations such as bioplastics, which are derived from renewable sources, and enhanced recycling technologies that allow for the recovery of plastics with minimal waste, are paving the way for a more sustainable future. These materials not only reduce reliance on fossil fuels but also contribute to a circular economy where products can be reused and repurposed.

Tips for manufacturers looking to incorporate innovative materials include evaluating the life cycle of materials used in their products. This assessment can highlight opportunities for substitution with more sustainable options. Additionally, fostering partnerships with research institutions can accelerate innovation, allowing companies to stay ahead in the competitive market. Lastly, engaging in consumer education about the benefits of eco-friendly plastics can enhance brand loyalty and attract environmentally conscious customers. By embracing these innovative materials, manufacturers can play a crucial role in shaping a greener future.

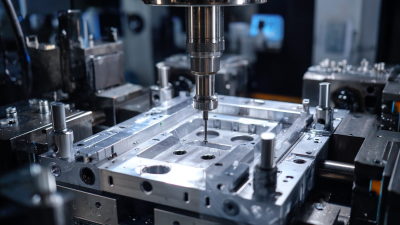

Revolutionizing Processes: Cutting-Edge Technologies in Plastic Production

The landscape of plastic manufacturing is undergoing a significant transformation powered by cutting-edge technologies that aim to streamline processes while enhancing sustainability. Innovations such as advanced polymerization techniques and 3D printing have emerged, enabling manufacturers to produce high-quality plastics with reduced environmental impact. By utilizing bio-based feedstocks and energy-efficient methods, these techniques not only lower carbon emissions but also contribute to a circular economy by facilitating recycling and repurposing.

Furthermore, automation and artificial intelligence are being integrated into production lines, optimizing efficiency and reducing waste. Smart sensors and data analytics allow for real-time monitoring and adjustments, ensuring that the manufacturing process remains agile and responsive to market demands. As companies embrace these revolutionary processes, they are not only redefining industry standards but also paving the way for a more sustainable future in plastic manufacturing, where innovation works hand in hand with environmental stewardship.

Innovations in Plastic Manufacturing: Sustainable Solutions for Tomorrow

This chart showcases the percentage of different innovative technologies being adopted in plastic manufacturing over the past few years, highlighting the shift towards sustainable solutions.

Circular Economy: Strategies for Reducing Plastic Waste in Manufacturing

The concept of a circular economy presents a transformative approach to plastic manufacturing by emphasizing the importance of reducing waste at every stage of the production process. Innovative strategies, such as designing for disassembly and incorporating recycled materials into manufacturing, are pivotal in shifting away from traditional linear production models. By rethinking product design, manufacturers can facilitate easier recycling, allowing materials to be reused repeatedly rather than ending up in landfills.

Moreover, collaboration across the entire supply chain plays a crucial role in achieving sustainability goals. Manufacturers can partner with suppliers who prioritize eco-friendly practices and technology advancements that enable the use of biodegradable or recyclable plastics. Implementing take-back programs and incentivizing customers to return products can further reduce plastic waste. As stakeholders increasingly recognize the environmental impact of plastic production, adopting circular economy principles not only benefits the ecosystem but can also lead to cost savings and enhanced brand reputation for manufacturers committed to sustainability.

Exploring Innovations in Plastic Manufacturing: Sustainable Solutions for Tomorrow

| Innovation | Description | Impact on Circular Economy | Sustainability Benefits |

|---|---|---|---|

| Biodegradable Plastics | Plastics made from natural materials that decompose over time. | Reduces landfill waste and encourages biodegradable options in the market. | Lower environmental impact and reduced dependencies on fossil fuels. |

| Recycled Plastics | Plastics that are processed and reused from existing plastic products. | Promotes resource recovery and decreases demand for new raw materials. | Conserves energy and reduces greenhouse gas emissions associated with production. |

| Bio-based Plastics | Plastics derived from renewable biological resources. | Supports sustainable agricultural practices and reduces petroleum reliance. | Lower carbon footprint and promotes a circular economy. |

| Closed-loop Recycling Systems | Systems that recycle materials back into their original form for remanufacturing. | Enhances recycling efficiency and minimizes waste generation. | Maximizes resource use and reduces environmental pollution. |

| Plant-based Additives | Natural additives to enhance the properties of plastics. | Supports reduction of harmful chemicals and increases recyclability. | Promotes safer and more sustainable product development. |

Smart Manufacturing: Integrating Digital Solutions for Sustainability

The integration of digital solutions in plastic manufacturing is transforming the industry towards a sustainable future. Smart manufacturing, which leverages technologies like IoT, AI, and big data analytics, is becoming increasingly vital in optimizing production processes. According to the "2022 Smart Manufacturing Report" by the International Society of Automation, companies that adopt smart manufacturing techniques see a 25-30% reduction in waste and a 20% increase in energy efficiency. This shift not only lowers operational costs but also significantly reduces the environmental footprint of plastic manufacturing.

The implementation of digital solutions enables real-time monitoring and predictive maintenance, ensuring machines operate efficiently and reducing downtime. A McKinsey report suggests that by 2030, smart manufacturing could generate up to $3.7 trillion in economic value while also achieving an impressive 45% reduction in greenhouse gas emissions across the manufacturing sector. By embracing these innovations, plastic manufacturers can adapt to the pressing demands for sustainability, ensuring their products meet the expectations of environmentally-conscious consumers and regulatory bodies alike. Adopting these smart technologies represents a crucial step towards creating a more sustainable and resilient industry for the future.

Collaboration for Change: Partnerships Driving Sustainable Practices in Plastics

Collaboration has emerged as a pivotal force in driving sustainable practices in the plastics industry. As we face an environmental crisis, partnerships among manufacturers, researchers, and non-profit organizations are crucial. According to a 2022 report by the Plastics Industry Association, 85% of plastic manufacturers believe that collaboration is key to achieving sustainability goals. By pooling resources and expertise, these partnerships can accelerate the development of eco-friendly materials and production techniques. For instance, initiatives like the Ellen MacArthur Foundation’s Plastics Pact have united stakeholders to work towards a circular economy, significantly reducing plastic waste.

Tips: Engage with local organizations to find collaboration opportunities. Join industry-specific forums to connect with other manufacturers who prioritize sustainability.

Furthermore, innovation in plastic manufacturing is increasingly dependent on shared knowledge and technology transfer between companies. A recent study indicated that companies involved in collaborative projects are 40% more likely to invest in sustainable innovations. These collaborations not only lead to the creation of biodegradable plastics but also improve recycling processes, maximizing resource efficiency.

Tips: Invest in training your team on the latest sustainable practices. Consider participating in sustainability workshops hosted by industry leaders to stay ahead of trends.

Related Posts

-

Innovative Molding Tools for Streamlined Manufacturing Processes

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products

-

Exploring the Future of Union Tool: Innovations and Applications in Today’s Industry

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency