Top 5 Benefits of Using Prototype Plastic Molding for Your Product Development

In the fast-paced world of product development, efficiency and innovation are paramount. One technology that has gained considerable traction is prototype plastic molding. Renowned industry expert Dr. Emily Carter, a leading figure in plastic manufacturing, once stated, "Prototype plastic molding is more than just a method; it's a gateway to optimizing design and accelerating time-to-market." This sentiment encapsulates the growing importance of this technique in modern product design.

Prototype plastic molding allows for rapid iteration, enabling developers to test concepts and refine their designs swiftly. As companies strive to bring new products to market faster than ever before, the benefits of employing prototype plastic molding become increasingly clear. From increased design flexibility to cost-effectiveness, this approach offers a myriad of advantages that can significantly enhance the product development process.

In this article, we will explore the top five benefits of using prototype plastic molding in your product development journey. By understanding these advantages, businesses can make informed decisions that not only streamline their processes but also improve the overall quality and functionality of their products.

Advantages of Rapid Prototyping in Product Development

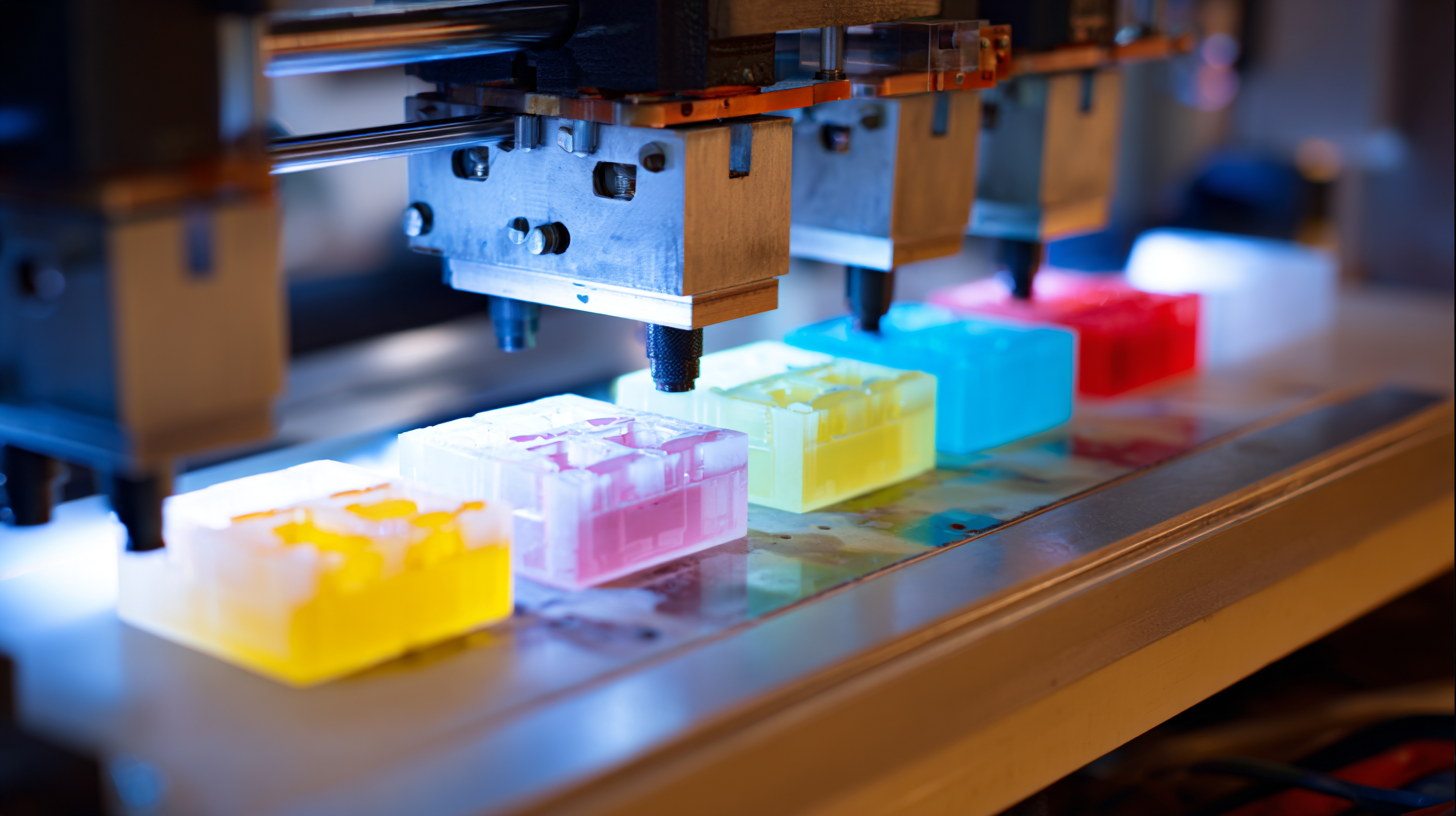

Rapid prototyping has transformed the landscape of product development, particularly when utilizing prototype plastic molding. One of the primary advantages of this method is speed. Traditional manufacturing processes can be time-consuming, but rapid prototyping allows designers to create models quickly, enabling faster iterations. This swift turnaround means that teams can evaluate design concepts, identify potential issues, and implement changes in a fraction of the time it would take with conventional methods.

In addition to speed, prototype plastic molding offers cost-effectiveness. Early-stage product development often incurs high costs, but using prototyping techniques reduces material waste and minimizes the need for expensive tooling. This allows companies to test multiple designs without breaking the bank, facilitating innovation and encouraging more creative approaches. Furthermore, the ability to produce functional prototypes allows for better testing and validation, ensuring that products meet user needs and expectations before full-scale production begins.

Cost Efficiency of Prototype Plastic Molding Solutions

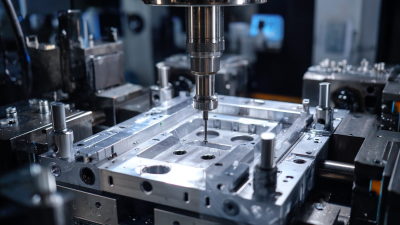

Prototype plastic molding offers significant cost efficiency, making it an attractive option for product development. One of the primary advantages is the reduction in production costs compared to traditional manufacturing methods. By utilizing prototype molding, companies can create and test product designs without the high expenses associated with full-scale production. This approach allows businesses to iterate quickly, making necessary adjustments to the design while minimizing financial risk.

Additionally, prototype plastic molding streamlines the overall development process. Designers can produce multiple iterations of a product in a shorter timeframe, allowing for faster feedback and revisions. This rapid prototyping not only cuts down on costs but also enhances the potential for innovation. By enabling a more flexible design process, companies can better align their products with market demands, ensuring they deliver high-quality items that meet customer expectations without overspending on production.

Top 5 Benefits of Using Prototype Plastic Molding for Your Product Development - Cost Efficiency of Prototype Plastic Molding Solutions

| Benefit | Description | Cost Efficiency |

|---|---|---|

| Rapid Prototyping | Allows for quick turnaround on product designs, enabling faster market entry. | Reduces overall development time and costs by minimizing delays. |

| Material Versatility | Supports various plastic materials, including ABS, PVC, and Polycarbonate. | Offers options that can lower material costs while meeting design specifications. |

| Design Flexibility | Enables alterations and improvements in design before final production. | Saves money by reducing the need for extensive revisions later in the process. |

| Lower Initial Investment | Prototype molding requires less upfront cost compared to traditional methods. | Allows startups and small businesses to invest in product development without high financial strain. |

| Reduced Waste | Minimizes material waste through precise manufacturing techniques. | Decreases costs associated with wasted materials and increases sustainability. |

Enhanced Design Flexibility with Prototype Plastics

When it comes to product development, one of the outstanding benefits of utilizing prototype plastic molding is the enhanced design flexibility it affords. Designers and engineers can bring their creative visions to life without the limitations often imposed by traditional manufacturing methods. This flexibility allows for quicker iterations and modifications, ensuring that the final product aligns closely with market needs and consumer preferences.

To maximize the advantages of prototype plastic molding, consider a few essential tips. First, engage in early collaboration with your molding partner. Sharing your design concepts and functionality goals upfront can lead to more innovative solutions and reduce costly revisions later on. Secondly, take advantage of advanced simulation software to visualize how your designs will perform. This proactive approach not only identifies potential issues but also fosters a more robust design process.

Additionally, don’t hesitate to experiment with different materials and textures. Prototype plastic molding offers a variety of options that can enhance the aesthetic and functional qualities of your product. By testing various combinations, you can discover what resonates best with your target audience while fine-tuning the overall design for optimal performance.

Improved Product Testing and Validation Processes

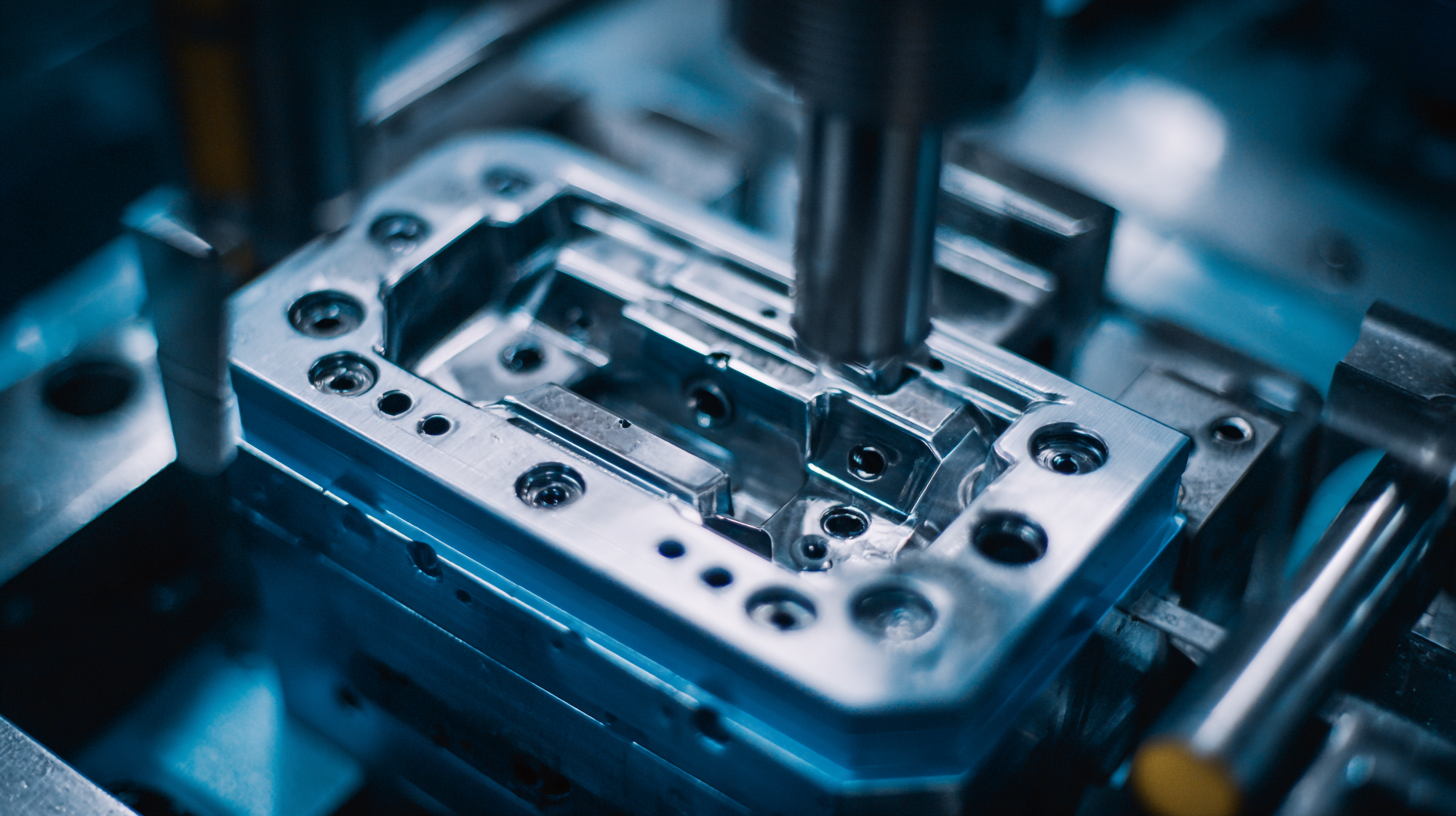

The use of prototype plastic molding significantly enhances the product testing and validation process, allowing companies to better assess and refine their designs before full-scale production. By creating prototypes quickly and cost-effectively, businesses can evaluate product functionality, ergonomics, and user interaction. This immediate feedback loop helps identify potential issues early in the development cycle, reducing the risk of costly changes later on.

Furthermore, prototype plastic molding facilitates thorough testing under real-world conditions. Engineers can simulate various environments and stress scenarios to assess how the product performs. This rigorous validation ensures that the final product meets both quality standards and customer expectations, reducing the likelihood of failure once launched. By prioritizing testing and validation, companies can create more reliable and market-ready products, ultimately leading to greater consumer satisfaction and reduced time-to-market.

Streamlined Time-to-Market with Prototyping Techniques

Prototyping with plastic molding plays a crucial role in streamlining the product development process, particularly in reducing time-to-market. By utilizing prototype plastic molding techniques, companies can rapidly create physical models of their products, allowing for faster iterations and improvements based on real-world feedback. This approach not only helps in identifying design flaws early but also accelerates decision-making, enabling teams to pivot quickly and align their offerings with market demands.

Prototyping with plastic molding plays a crucial role in streamlining the product development process, particularly in reducing time-to-market. By utilizing prototype plastic molding techniques, companies can rapidly create physical models of their products, allowing for faster iterations and improvements based on real-world feedback. This approach not only helps in identifying design flaws early but also accelerates decision-making, enabling teams to pivot quickly and align their offerings with market demands.

Moreover, the integration of advanced technologies in prototyping, such as AI and digital twins, enhances the process further. These innovations enable manufacturers to simulate product performance and optimize designs before moving to full-scale production. As the landscape for product development evolves, leveraging prototype plastic molding with such technologies becomes essential for businesses aiming to ensure quality, efficiency, and rapid delivery of market-ready products. This agility is particularly beneficial for startups looking to make a splash in competitive markets, highlighting the significance of adopting effective prototyping techniques.

Related Posts

-

Exploring Innovations in Plastic Manufacturing: Sustainable Solutions for Tomorrow

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

How Injection Mold Manufacturing is Revolutionizing Product Development in 2023

-

Exploring the Future of Union Tool: Innovations and Applications in Today’s Industry

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products

-

What is Plastic Mold Injection Machine? A Comprehensive Guide to Its Types and Applications